Kaist

Korean

News

College of Engineering News

-

A Molecular Sensor for In-Situ Analysis of Complex..

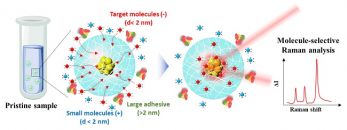

A KAIST research group presented a molecular sensor with a microbead format for the rapid in-situ detection of harmful molecules in biological fluids or foods in a collaboration with a Korea Institute of Materials Science (KIMS) research group. As the sensor is designed to selectively concentrate charged small molecules and amplify the Raman signal, no time-consuming pretreatment of samples is required. Raman spectra are commonly known as molecular fingerprints. However, their low intensity has restricted their use in molecular detection, especially for low concentrations. Raman signals can be dramatically amplified by locating the molecules on the surface of metal nanostructures where the electromagnetic field is strongly localized. However, it is still challenging to use Raman signals for the detection of small molecules dissolved in complex biological fluids. Adhesive proteins irreversibly adsorb on the metal surface, which prevents the access of small target molecules onto the metal surface. Therefore, it was a prerequisite to purify the samples before analysis. However, it takes a long time and is expensive. A joint team from Professor Shin-Hyun Kim’s group in KAIST and Dr. Dong-Ho Kim’s group in KIMS has addressed the issue by encapsulating agglomerates of gold nanoparticles using a hydrogel. The hydrogel has three-dimensional network structures so that molecules smaller than the mesh are selectively permeable. Therefore, the hydrogel can exclude relatively large proteins, while allowing the infusion of small molecules. Therefore, the surface of gold nanoparticles remains intact against proteins, which accommodates small molecules. In particular, the charged hydrogel enables the concentration of oppositely-charged small molecules. That is, the purification is autonomously done by the materials, removing the need for time-consuming pretreatment. As a result, the Raman signal of small molecules can be selectively amplified in the absence of adhesive proteins. Using the molecular sensors, the research team demonstrated the direct detection of fipronil sulfone dissolved in an egg without sample pretreatment. Recently, insecticide-contaminated eggs have spread in Europe, South Korea, and other countries, threatening health and causing social chaos. Fipronil is one of the most commonly used insecticides for veterinary medicine to combat fleas. The fipronil is absorbed through the chicken skin, from which a metabolite, fipronil sulfone, accumulates in the eggs. As the fipronil sulfone carries partial negative charges, it can be concentrated using positively-charged microgels while excluding adhesive proteins in eggs, such as ovalbumin, ovoglobulin, and ovomucoid. Therefore, the Raman spectrum of fipronil sulfone can be directly measured. The limit of direct detection of fipronil sulfone dissolved in an egg was measured at 0.05 ppm. Professor Kim said, “The molecular sensors can be used not only for the direct detection of harmful molecules in foods but also for residual drugs or biomarkers in blood or urine.” Dr. Dong-Ho Kim said, “It will be possible to save time and cost as no sample treatment is required.” This research was led by graduate student Dong Jae Kim and an article entitled “SERS-Active Charged Microgels for Size- and Charge-Selective Molecular Analysis of Complex Biological Samples” was published on October 4, 2018 in Small and featured on the inside cover of the journal. Figure 1. Schematic illustrating the concentration of charged small molecules and the exclusion of large adhesive proteins using a charged hydrogel microbead containing an agglomerate of gold nanoparticles. The Raman signal of the small molecules is selectively amplified by the agglomerate. Figure 2. Confocal laser scanning microscope images showing the concentration of oppositely charged molecules, where negatively-charged microgels are denoted by red circles and positively-charged microgels are denoted by blue circles. Green fluorescence originates from negatively-charged dye molecules and red fluorescence originates from positively-charged dye molecules. Figure 3. Raman spectra measured from fipronil sulfone-spiked eggs, where the concentrations of fipronil sulfone are denoted; 0 ppm indicates no fipronil sulfone in the egg. The characteristic peaks of fipronil sulfone are denoted by the dotted lines.

-

Mussel-Inspired Defect Engineering Enhances the Me..

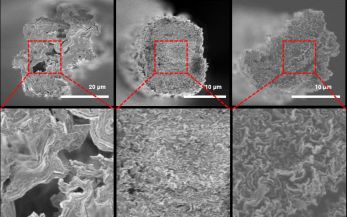

Researchers demonstrated the mussel-inspired reinforcement of graphene fibers for the improvement of different material properties. A research group under Professor Sang Ouk Kim applied polydopamine as an effective infiltrate binder to achieve high mechanical and electrical properties for graphene-based liquid crystalline fibers. This bio-inspired defect engineering is clearly distinguishable from previous attempts with insulating binders and proposes great potential for versatile applications of flexible and wearable devices as well as low-cost structural materials. The two-step defect engineering addresses the intrinsic limitation of graphene fibers arising from the folding and wrinkling of graphene layers during the fiber-spinning process. Bio-inspired graphene-based fiber holds great promise for a wide range of applications, including flexible electronics, multifunctional textiles, and wearable sensors. In 2009, the research group discovered graphene oxide liquid crystals in aqueous media while introducing an effective purification process to remove ionic impurities. Graphene fibers, typically wet-spun from aqueous graphene oxide liquid crystal dispersion, are expected to demonstrate superior thermal and electrical conductivities as well as outstanding mechanical performance. Nonetheless, owing to the inherent formation of defects and voids caused by bending and wrinkling the graphene oxide layer within graphene fibers, their mechanical strength and electrical/thermal conductivities are still far below the desired ideal values. Accordingly, finding an efficient method for constructing the densely packed graphene fibers with strong interlayer interaction is a principal challenge. Professor Kim's team focused on the adhesion properties of dopamine, a polymer developed with the inspiration of the natural mussel, to solve the problem. This functional polymer, which is studied in various fields, can increase the adhesion between the graphene layers and prevent structural defects. Professor Kim’s research group succeeded in fabricating high-strength graphene liquid crystalline fibers with controlled structural defects. They also fabricated fibers with improved electrical conductivity through the post-carbonization process of polydopamine. Based on the theory that dopamine with subsequent high temperature annealing has a similar structure with that of graphene, the team optimized dopamine polymerization conditions and solved the inherent defect control problems of existing graphene fibers. They also confirmed that the physical properties of dopamine are improved in terms of electrical conductivity due to the influence of nitrogen in dopamine molecules, without damaging the conductivity, which is the fundamental limit of conventional polymers. Professor Kim, who led the research, said, "Despite its technological potential, carbon fiber using graphene liquid crystals still has limits in terms of its structural limitations." This technology will be applied to composite fiber fabrication and various wearable textile-based application devices." This work, in which Dr. In-Ho Kim participated as first author was selected as a front cover paper of Advanced Materials on October 4. This research was supported by the National Creative Research Initiative (CRI) Center for Multi-Dimensional Directed Nanoscale Assembly and the Nanomaterial Technology Development Program through the National Research Foundation of Korea funded by the Ministry of Science and ICT. Figure 1. Cross-section SEM image of pure graphene fiber (left) and that of graphene fiber after two-stage defect control using polydopamine (middle and right).

-

KAIST Presents a Technology for Reducing the Drag ..

(from left: Professor Yeunwoo Cho and PhD Jaeho Chung) Professor Yeunwoo Cho and his team from the Department of Mechanical Engineering developed new technology that reduces the drag force of a moving body in a still fluid by using the supercavitation phenomenon. When a body moves in air, the frictional drag is lower than that of the same body moving in water. Therefore, the body that moves in water can reduce the drag significantly when it is completely enveloped in a gaseous cavity. The team used compressed air to create so-called supercavitation, which is a phenomenon created by completely enveloping a body in a single large gaseous cavity. The drag force exerted on the body is then measured. As a result, the team confirmed that the drag force for a moving body enveloped in air is about 25% of the drag force for a moving body without envelopment. These results can be applied for developing high-speed underwater vehicles and the development of air-lubricated, high-speed vessels. The team expects that the results can be applied for developing high-speed underwater vehicles and the development of air lubrication for a ship’s hull. This research, led by PhD Jaeho Chung, was published in the Journal of Fluid Mechanics as a cover article on November 10, 2018. Figure 1. The cover article of the Journal of Fluid Mechanics Vol. 854

-

Highly Scalable Process to Obtain Stable 2D Nanosh..

(Professor Do Hyun Kim and his team) A KAIST team developed technology that allows the mass production of two-dimensional (2D) nanomaterial dispersion by utilizing the characteristic shearing force of hydraulic power. The 2D nanosheet dispersion can be directly applied to solution-based processes to manufacture devices for electronics as well as energy storage and conversion. It is expected to be used in these devices with improved performance. There have been numerous researches on the mass production of various 2D nanomaterial because they show outstanding physical and chemical characteristics when they are truly 2D. With strong mechanical force or chemical reaction only, each existing exfoliation method has its limitation to make 2D material when the scale of manufacturing increases. They also face the issues of high cost and long process time. Moreover, 2D nanosheets by the exfoliation have the tendency of agglomeration due to the surface energy. Usually, organic solvent or surfactant is required to obtain high yield and concentration of 2D material by minimizing agglomeration. After several years of research, Professor Do Hyun Kim in the Department of Chemical and Biomolecular Engineering and his team verified that optimized shearing in their reactor provided the highest efficiency for the exfoliation of nanomaterial. For the increased reactor capacity, they selected a flow and a dispersive agent to develop a high-speed, mass-production process to get 2D nanosheets by physical exfoliation with an aqueous solution. The team proposed a flow reactor based on Taylor-Couette flow, which has the advantage of high shear rate and mixing efficiency even under large reactor capacity. In this research, Professor Young-Kyu Han at Dongguk University-Seoul carried out the Ab initio calculation to select the dispersive agent. According to his calculation, an ionic liquid can stabilize and disperse 2D nanomaterial even in a small concentration. This calculation could maximize the exfoliating efficiency. Professor Bong Gill Choi at Kangwon National University carried out the evaluation of device made of resulting dispersion. The team used a membrane filtration process to make a flexible and highly conductive film of 2D material. The film was then applied to produce an electrode for the supercapacitor device with very high capacity per volume. They also confirmed its stability in their supercapacitor device. Additionally, they applied dispersive nanomaterials including graphene, molybdenum disulfide (MoS₂), and boron nitride (BN) to inkjet printer ink and realized micrometer-thick nanomaterial patterns on A4 paper. The graphene ink showed no loss of electrical property after printing without additional heat treatment. Professor Kim said, “This new technology for the high-speed mass production of nanomaterials can easily be applied to various 2D nanomaterials. It will accelerate the production of highly efficient devices for optoelectronics, biosensors, and energy storage/conversion units with low cost.” This research, led by Dr. Jae-Min Jeong, was published in Advanced Functional Materials on August 12. Figure 1. The cover page of Advanced Functional Materials

-

Washing and Enrichment of Micro-Particles Encapsul..

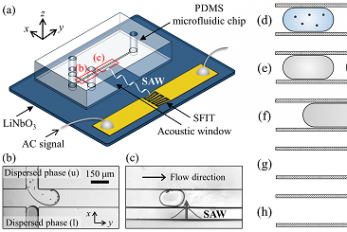

Researchers developed microfluidic technology for the washing and enrichment of in-droplet micro-particles. They presented the technology using a microfluidic chip based on surface acoustic wave (SAW)-driven acoustic radiation force (ARF). The team demonstrated the first instance of acoustic in-droplet micro-particle washing with a particle recovery rate of approximately 90 percent. They further extended the applicability of the proposed method to in-droplet particle enrichment with the unprecedented abilities to increase the in-droplet particle quantity and exchange the droplet dispersed phase. This proposed method enabled on-chip, label-free, continuous, and selective in-droplet micro-particle manipulation. The team demonstrated the first instance of in-droplet micro-particle washing between two types of alternating droplets in a simple microchannel, proving that the method can increase the particle quantity, which has not been achieved by previously reported methods. The study aimed to develop an in-droplet micro-particle washing and enrichment method based on SAW-driven ARF. When a droplet containing particles is exposed to an acoustic field, both the droplet and suspended particles experience ARF arising from inhomogeneous wave scattering at the liquid-liquid and liquid-solid interfaces. Unlike previous in-droplet particle manipulation methods, this method allows simultaneous and precise control over the droplets and suspended particles. Moreover, the proposed acoustic method does not require labelled particles, such as magnetic particles, and employs a simple microchannel geometry. Microfluidic sample washing has emerged as an alternative to centrifugation because the limitations of centrifugation-based washing methods can be addressed using continuous washing processes. It also has considerable potential and importance in a variety of applications such as single-cell/particle assays, high-throughput screening of rare samples, and cell culture medium exchange. Compared to continuous flow-based microfluidic methods, droplet-based microfluidic sample washing has been rarely explored due to technological difficulties. On-chip, in-droplet sample washing requires sample transfer across the droplet interface composed of two immiscible fluids. This process involves simultaneous and precise control over the encapsulated sample and droplet interface during the medium exchange of the in-droplet sample. Sample encapsulation within individual microscale droplets offers isolated microenvironments for the samples. Experimental uncertainties due to cross-contamination and Taylor dispersion between multiple reagents can be reduced in droplet-based microfluidics. This is the first research achievement made by the Acousto-Microfluidics Research Center for Next-Generation Healthcare, the cross-generation collaborative lab KAIST opened in May. This novel approach pairs senior and junior faculty members for sustaining the research legacy even after the senior researcher retires. The research center, which paired Chair Professor Hyung Jin Sung and Professors Hyoungsoo Kim and Yeunwoo Cho, made a breakthrough in microfluidics along with PhD candidate Jinsoo Park. The study was featured as the cover of Lab on a Chip published by Royal Society of Chemistry. Jinsoo Park, first author of the study, believes this technology will may serve as an in-droplet sample preparation platform with in-line integration of other droplet microfluidic components. Chair Professor Sung said, “The proposed acoustic method will offer new perspectives on sample washing and enrichment by performing the operation in microscale droplets.” Figure 1. (a) A microfluidic device for in-droplet micro-particle washing and enrichment; (b) alternatingly produced droplets of two kinds at a double T-junction; (c) a droplet and encapsulated micro-particles exposed to surface acoustic wave-driven acoustic radiation force; (d-h) sequential processes of in-droplet micro-particle washing and enrichment operation.

-

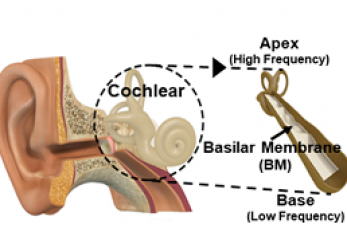

Flexible Piezoelectric Acoustic Sensors for Speake..

A KAIST research team led by Professor Keon Jae Lee from the Department of Material Science and Engineering has developed a machine learning-based acoustic sensor for speaker recognition. Acoustic sensors were spotlighted as one of the most intuitive bilateral communication devices between humans and machines. However, conventional acoustic sensors use a condenser-type device for measuring capacitance between two conducting layers, resulting in low sensitivity, short recognition distance, and low speaker recognition rates. The team fabricated a flexible piezoelectric membrane by mimicking the basilar membrane in the human cochlear. Resonant frequencies vibrate corresponding regions of the trapezoidal piezoelectric membrane, which converts voice to electrical signal with a highly sensitive self-powered acoustic sensor. This multi-channel piezoelectric acoustic sensor exhibits sensitivity more than two times higher and allows for more abundant voice information compared to conventional acoustic sensors, which can detect minute sounds from farther distances. In addition, the acoustic sensor can achieve a 97.5% speaker recognition rate using a machine learning algorithm, reducing by 75% error rate than the reference microphone. AI speaker recognition is the next big thing for future individual customized services. However, conventional technology attempts to improve recognition rates by using software upgrades, resulting in limited speaker recognition rates. The team enhanced the speaker recognition system by replacing the existing hardware with an innovative flexible piezoelectric acoustic sensor. Further software improvement of the piezoelectric acoustic sensor will significantly increase the speaker and voice recognition rate in diverse environments. Professor Lee said, “Highly sensitive self-powered acoustic sensors for speaker recognition can be used for personalized voice services such as smart home appliances, AI secretaries, always-on IoT, biometric authentication, and FinTech.” These research “Basilar Membrane-Inspired Self-Powered Acoustic Sensor” and “Machine Learning-based Acoustic Sensor for Speaker Recognition” were published in the September 2018 issue of Nano Energy. Firgure 1: A flexible piezoelectric acoustic sensor mimicking the human cochlear. Figure 2: Speaker recognition with a machine learning algorithm.

-

Engineered E. coli Using Formic Acid and CO2 As a ..

(Figure: Formic acid and CO2 assimilation pathways consisting of the reconstructed THF cycle and reverse glycine cleavage reaction. This schematic diagram shows the formic acid and CO2 assimilation procedure through the pathway. Plasmids used in this study and the genetic engineering performed in this study are illustrated.) A research group at KAIST has developed an engineered E. coli strain that converts formic acid and CO2 to pyruvate and produces cellular energy from formic acid through reconstructed one-carbon pathways. The strategy described in this study provides a new platform for producing value-added chemicals from one-carbon sources. Formic acid is a carboxylic acid composed of one carbon. Formic acid was produced from CO2 by the chemical method. Recently, the C1 Gas Refinery R&D Center has successfully developed a biological process that produces formic acid from carbon monoxide for the first time. Formic acid is in a liquid state when at room temperature and atmospheric pressure. In addition, it is chemically stable and less toxic, thus, easy to store and transport. Therefore, it can be used as an alternative carbon source in the microbial fermentation process. In order to produce value-added chemicals using formic acid, a metabolic pathway that converts formic acid into cellular molecules composed of multiple carbons is required. However, a metabolic pathway that can efficiently convert formic acid into cellular molecules has not been developed. This acted as an obstacle for the production of value-added chemicals using formic acid A research group of Ph.D. student Junho Bang and Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering addressed this issue. This study, entitled “Assimilation of Formic Acid and CO2 by Engineered Escherichia coli Equipped with Reconstructed One-Carbon Assimilation Pathways”, has been published online in the Proceedings of the National Academy of Sciences of the United States of America (PNAS) on September 18. There has been increasing interest in utilizing formic acid as an alternative carbon source for the production of value-added chemicals. This research reports the development of an engineered E. coli strain that can convert formic acid and CO2 to pyruvate and produce cellular energy from formic acid through the reconstructed one-carbon pathways. The metabolic pathway that efficiently converts formic acid and CO2 into pyruvate was constructed by the combined use of the tetrahydrofolate cycle and reverse glycine cleavage reaction. The tetrahydrofolate cycle was reconstructed by utilizing Methylobacterium extorquens formate-THF ligase, methenyl-THF cyclohydrolase, and methylene-THF dehydrogenase. The glycine cleavage reaction was reversed by knocking out the repressor gene (gcvR) and overexpressing the gcvTHP genes that encode enzymes related with the glycine cleavage reaction. Formic acid and CO2 conversion to pyruvate was increased via metabolic engineering of the E. coli strain equipped with the one-carbon assimilation pathway. In addition, in order to reduce glucose consumption and increase formic acid consumption, Candida boidnii formate dehydrogenase was additionally introduced to construct a cellular energy producing pathway from formic acid. This reduces glucose consumption and increases formic acid consumption. The reconstructed one-carbon pathways can supply cellular molecules and cellular energies from the formic acid and CO2. Thus, the engineered E. coli strain equipped with the formic acid and CO2 assimilation pathway and cellular energy producing pathway from formic acid showed cell growth from formic acid and CO2 without glucose. Cell growth was monitored and 13C isotope analysis was performed to confirm E. coli growth from the formic acid and CO2. It was found that the engineered E. coli strain sustained cell growth from the formic acid and CO2 without glucose. Professor Lee said, “To construct the C1-refinery system, a platform strain that can convert one-carbon materials to higher carbon materials needs to be developed. In this report, a one-carbon pathway that can efficiently convert formic acid and CO2 to pyruvate was developed and a cellular energy producing pathway from formic acid was introduced. This resulted in an engineered E. coli strain that can efficiently utilize formic acid as a carbon source while glucose consumption was reduced. The reconstructed one-carbon pathways in this research will be useful for the construction of the C1-refinery system.” This work was supported by the C1 Gas Refinery Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (NRF-2016M3D3A1A01913250). For further information: Sang Yup Lee, Distinguished Professor of Chemical and Biomolecular Engineering, KAIST (leesy@kaist.ac.kr, Tel: +82-42-350-3930)

-

KAIST Perfectly Transfers Nanowires onto a Flexibl..

(from left: PhD Min-Ho Seo and Professor Jun-Bo Yoon) Boasting excellent physical and chemical properties, nanowires (NWs) are suitable for fabricating flexible electronics; therefore, technology to transfer well-aligned wires plays a crucial role in enhancing performance of the devices. A KAIST research team succeeded in developing NW-transfer technology that is expected to enhance the existing chemical reaction-based NW fabrication technology that has this far showed low performance in applicability and productivity. NWs, one of the most well-known nanomaterials, have the structural advantage of being small and lightweight. Hence, NW-transfer technology has drawn attention because it can fabricate high-performance, flexible nanodevices with high simplicity and throughput. A conventional nanowire-fabrication method generally has an irregularity issue since it mixes chemically synthesized nanowires in a solution and randomly distributes the NWs onto flexible substrates. Hence, numerous nanofabrication processes have emerged, and one of them is master-mold-based, which enables the fabrication of highly ordered NW arrays embedded onto substrates in a simple and cost-effective manner, but its employment is limited to only some materials because of its chemistry-based NW-transfer mechanism, which is complex and time consuming. For the successful transfer, it requires that adequate chemicals controlling the chemical interfacial adhesion between the master mold, NWs, and flexible substrate be present. Here, Professor Jun-Bo Yoon and his team from the School of Electrical Engineering introduced a material-independent mechanical-interlocking-based nanowire-transfer (MINT) method to fabricate ultralong and fully aligned NWs on a large flexible substrate in a highly robust manner. This method involves sequentially forming a nanosacrificial layer and NWs on a nanograting substrate that becomes the master mold for the transfer, then weakening the structure of the nanosacrificial layer through a dry etching process. The nanosacrificial layer very weakly holds the nanowires on the master mold. Therefore, when using a flexible substrate material, the nanowires are very easily transferred from the master mold to the substrate, just like a piece of tape lifting dust off a carpet. This technology uses common physical vapor deposition and does not rely on NW materials, making it easy to fabricate NWs onto the flexible substrates. Using this technology, the team was able to fabricate a variety of metal and metal-oxide NWs, including gold, platinum, and copper – all perfectly aligned on a flexible substrate. They also confirmed that it can be applied to creating stable and applicable devices in everyday life by successfully applying it to flexible heaters and gas sensors. PhD Min-Ho Seo who led this research said, “We have successfully aligned various metals and semiconductor NWs with excellent physical properties onto flexible substrates and applied them to fabricated devices. As a platform-technology, it will contribute to developing high-performing and stable electronic devices.” This research was published in ACS Nano on May 24. Figure 1. Photograph of the fabricated wafer-scale fully aligned and ultralong Au nanowire array on a flexible substrate

-

President Shin Presents Opportunities & Challenges..

(President Shin makes a keynote speech at the 2018 Summer Davos Forum in China on Sept.20.) KAIST co-hosted the Asia Session with the World Economic Forum during the 2018 Summer Davos Forum in Tianjin, China from September 18 through 20. The session highlighted regional collaboration in Asia to promote inclusive growth in the Fourth Industrial Revolution. KAIST is working closely with the WEF to take the lead in the Fourth Industrial Revolution. Last July, KAIST established the Fourth Industrial Revolution Information Center (FIRIC) at the KAIST Institute and signed an MOU with the Center for the Fourth Industrial Revolution (C4IR) at the WEF in October. The session is a follow-up event KAIST and the C4IR agreed to last year during the Roundtable Session held in Seoul. Many experts in new emerging industries as well as many project directors, including Director Murat Sonmez of the C4IR, attended the session KAIST hosted. Director Chizuru Suga at the C4IR in Japan, Director Danil Kerimi in China, and Director Shailesh Sharda in India also attended the session and discussed ways to expand collaboration and networks among the countries. In his keynote speech at the session on September 20, President Sung-Chul Shin presented how the Korean government is trying to drive the economy by strategically investing in focused industries in the new global industrial environment. President Shin introduced the government’s strategic roadmap to build the competitiveness of emerging technologies such as AI, blockchain, and precision medicine. He also stressed that the three components of innovation, collaboration, and speed should be prioritized in all sectors for the successful realization of the Fourth Industrial Revolution. For instance, innovation in education, research, and technology commercialization, expansive domestic and international collaboration beyond the private and public sectors, speedy deregulation, and efficient governance will all be critical. He also said that KAIST will launch new pilot collaboration projects along with the WEF soon. “We paved the way for leading the network with major countries including Japan and India for advancing the Fourth Industrial Revolution through this session,” President Shin said.

-

Silk Adhesive Paves the Way for Epidermal Electron..

(from left: Dr. Ji-Won Seo, Professor Hyunjoo Jenny Lee and PhD candidate, Hyojung Kim) Producing effective epidermal electronics requires a strong, biocompatible interface between a biological surface and a sensor. Here, a KAIST team employed a calcium-modified silk fibroin as a biocompatible and strong adhesive. This technology led to the development of epidermal electronics with strong adhesion for patients who need drug injections and physiological monitoring over a long time. Recently, biocompatible silk fibroins has been increasingly used for flexible substrates and water-soluble sacrificial layers because they allow structural modifications and are biodegradable. From previous studies, the team discovered the adhesive properties of silk fibroin via metal chelate bonding and the water-capturing of Ca ions. Professor Hyunjoo Jenny Lee from the School of Electrical Engineering and her team explored ways to develop reusable, water-degradable, biocompatible and conductive epidermal electronics that can be attached to the human skin for long-term use. To overcome the limitations of conventional silk fibroin, the team introduced Ca ions to modify silk fibroin into a strong and biocompatible adhesive. Calcium ions adopted in silk fibroins serve to capture water and enhance the cohesion force through metal chelation. Therefore, this endows viscoelasticity to previously a firm silk fibroin. This modified silk fibroin exhibits strong viscoelasticity and strong adhesiveness when physically attached to the human skin and various polymer substrates. Their developed silk adhesive is reusable, water-degradable, biocompatible, and conductive. To test the effectiveness, the team employed the silk adhesive to fabricate an epidermal capacitive touch sensor that can be attached to the human skin. They verified the reusability of the sensor by performing attachment and detachment tests. They also confirmed that the physical adhesion of the Ca-modified silk facilitates its reusability and possesses high peel strength. Furthermore, they tested the stretchability of the silk adhesive on bladder tissue. Although it is not an epidermal skin, bladder tissue is highly stretchable. Hence, it is a perfect target to measure the resistance-strain characteristic of the silk adhesive. When the bladder tissue was stretched, the resistive strain epidermal sensor corresponded to the tensile strain. Showing high biocompatibility, the silk adhesive is suitable for interfacing with the human skin for a long period of time. Therefore, it can also be applied to a drug delivery epidermal system as well as an electrocardiogram (ECG) epidermal sensor. Professor Lee said, “We are opening up a novel use for silk by developing reusable and biodegradable silk adhesive using biocompatible silk fibroin. This technology will contribute to the development of next-generation epidermal electronics as well as drug delivery systems. This research, led by Dr. Ji-Won Seo and a PhD candidate, Hyojung Kim, was published in Advanced Functional Materials on September 5, 2018. Figure 1. Schematic and photograph of a hydrogel patch adhered on the human skin through the silk adhesive Figure 2. Cover page of Advanced Functional Materials

-

Spray Coated Tactile Sensor on a 3-D Surface for R..

Robots will be able to conduct a wide variety of tasks as well as humans if they can be given tactile sensing capabilities. A KAIST research team has reported a stretchable pressure insensitive strain sensor by using an all solution-based process. The solution-based process is easily scalable to accommodate for large areas and can be coated as a thin-film on 3-dimensional irregularly shaped objects via spray coating. These conditions make their processing technique unique and highly suitable for robotic electronic skin or wearable electronic applications. The making of electronic skin to mimic the tactile sensing properties of human skin is an active area of research for various applications such as wearable electronics, robotics, and prosthetics. One of the major challenges in electronic skin research is differentiating various external stimuli, particularly between strain and pressure. Another issue is uniformly depositing electrical skin on 3-dimensional irregularly shaped objects. To overcome these issues, the research team led by Professor Steve Park from the Department of Materials Science and Engineering and Professor Jung Kim from the Department of Mechanical Engineering developed electronic skin that can be uniformly coated on 3-dimensional surfaces and distinguish mechanical stimuli. The new electronic skin can also distinguish mechanical stimuli analogous to human skin. The structure of the electronic skin was designed to respond differently under applied pressure and strain. Under applied strain, conducting pathways undergo significant conformational changes, considerably changing the resistance. On the other hand, under applied pressure, negligible conformational change in the conducting pathway occurs; e-skin is therefore non-responsive to pressure. The research team is currently working on strain insensitive pressure sensors to use with the developed strain sensors. The research team also spatially mapped the local strain without the use of patterned electrode arrays utilizing electrical impedance tomography (EIT). By using EIT, it is possible to minimize the number of electrodes, increase durability, and enable facile fabrication onto 3-dimensional surfaces. Professor Park said, “Our electronic skin can be mass produced at a low cost and can easily be coated onto complex 3-dimensional surfaces. It is a key technology that can bring us closer to the commercialization of electronic skin for various applications in the near future.” The result of this work entitled “Pressure Insensitive Strain Sensor with Facile Solution-based Process for Tactile Sensing Applications” was published in the August issue of ACS Nano as a cover article. (Figure: Detecting mechanical stimuli using electrical impedance tomography

-

KAIST First Reveals Principles behind Electron Hea..

(from left: Professor Wonho Choe and Research Professor Sanghoo Park) A KAIST research team successfully identified the underlying principles behind electron heating, which is one of the most important phenomena in plasmas. As the electric heating determines wide range of physical and chemical properties of plasmas, this outcome will allow relevant industries to extend and effectively customize a range of plasma characteristics for their specific needs. Plasma, frequently called the fourth state of matter, can be mostly formed by artificially energizing gases in standard temperature (25°C) and pressure (1 atm) range. Among the many types of plasma, atmospheric-pressure plasmas have been gaining a great deal of attention due to their unique features and applicability in various scientific and industrial fields. Because plasma characteristics strongly depends on gas pressure in the sub-atmospheric to atmospheric pressure range, characterizing the plasma at different pressures is a prerequisite for understanding the fundamental principles of plasmas and for their industrial applications. In that sense, information on the spatio-temporal evolution in the electron density and temperature is very important because various physical and chemical reactions within a plasma arise from electrons. Hence, electron heating has been an interesting topic in the field of plasma. Because collisions between free electrons and neutral gases are frequent under atmospheric-pressure conditions, there are physical limits to measuring the electron density and temperature in plasmas using conventional diagnostic tools, thus the principles behind free electron heating could not be experimentally revealed. Moreover, lacking information on a key parameter of electron heating and its controlling methods is troublesome and limit improving the reactivity and applicability of such plasmas. To address these issues, Professor Wonho Choe and his team from the Department of Nuclear and Quantum Engineering employed neutral bremsstrahlung-based electron diagnostics in order to accurately examine the electron density and temperature in target plasmas. In addition, a novel imaging diagnostics for two dimensional distribution of electron information was developed. Using the diagnostic technique they developed, the team measured the nanosecond-resolved electron temperature in weakly ionized collisional plasmas, and they succeeded in revealing the spatiotemporal distribution and the fundamental principle involved in the electron heating process. The team successfully revealed the fundamental principle of the electron heating process under atmospheric to sub-atmospheric pressure (0.25-1atm) conditions through conducting the experiment on the spatiotemporal evolution of electron temperature. Their findings of the underlying research data on free electrons in weakly ionized collisional plasmas will contribute to enhancing the field of plasma science and their commercial applications. Professor Choe said, “The results of this study provide a clear picture of electron heating in weakly ionized plasmas under conditions where collisions between free electrons and neutral particles are frequent. We hope this study will be informative and helpful in utilizing and commercializing atmospheric-pressure plasma sources in the near future.” Articles related to this research, led by Research Professor Sanghoo Park, were published in Scientific Reports on May 14 and July 5. Figure 1. Nanosecond-resolved visualization of the electron heating structure. Spatiotemporal evolution of 514.5-nm continuum radiation,Te, Ar I emission Figure 2. Nanosecond-resolved visualization of electron heating. Spatiotemporal evolution of neutral bremsstrahlung at 514.5 nm