Kaist

Korean

-

Developing band-type lithium..

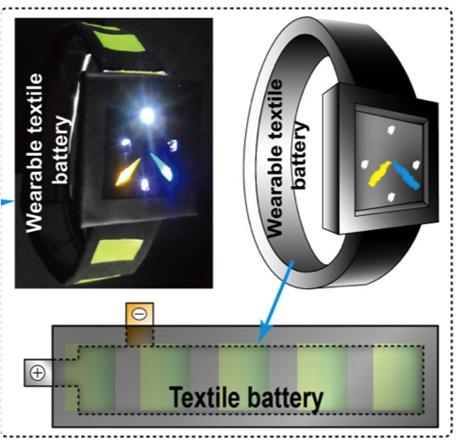

Prof. Jang Wook Choi’s group has established a wearable rechargeable battery technology that utilizes textiles (see the image below). Based on this original technology, his group is currently undertaking commercialization research under collaboration with KHVatech. KHVatech invested KRW 1,000,000,000 for pilot-scale research, including equipment and other relevant facilities on the Moonji campus. Both groups are on track to produce proto-type samples at present. They plan to finish the pilot-scale research by later this year and initiate a promotion targeting major IT companies as well as to start to develop manufacturing lines for large-scale production. Figure. Band-type wearable Li-ion batteries for smart watches. (Left) Actual demonstration of a band-type battery and (right) its schematic illustration. (Bottom) battery cell configuration based on textiles. Figure. Band-type wearable Li-ion batteries for smarwatches. (Left) Actual demonstration of band-type battery and (right) its schematic illustration. (Bottom) battery cell configuration based on textiles.

- DepartmentThe Graduate School of EEWS

- ProfessorChoi Jang Wook

-

Development of a virtual cel..

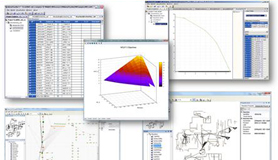

Metabolic engineering can be defined as a technology to overproduce industrially useful chemicals using microorganisms from renewable biomass feedstocks. A typical example is the redesign of the intracellular metabolic fluxes of a microorganism to force them towards target chemicals through computational and molecular biological tools. However, redesigning metabolic fluxes favorably towards target chemicals is extremely complex due to the thousands of enzymatic reactions occurring within the microbial host. To establish an effective metabolic engineering strategy, our laboratory has developed a software program called MetaFluxNet for the modeling and simulation of metabolic networks. MetaFluxNet supports large-scale network modeling and simulations to handle biochemical reactions in living organisms and predict metabolic fluxes under genetically and/or environmentally perturbed conditions. Ultimately, MetaFluxNet can help design strategies for metabolic engineering by predicting gene manipulation targets for the enhanced production of target chemicals prior to experiments. The recently updated MetaFluxNet 3.0 provides useful visualization functions for metabolic models and simulation results as well as new simulation algorithms. Technology transfer of the MetaFluxNet software package was made to notable companies, such as the Samsung Advanced Institute of Technology and GS Caltex for the development of industrial microorganisms in addition to other academic institutes, such as the National University of Singapore and Chungbuk National University.

- DepartmentDepartment of Chemical and Biomolecular Engineering

- ProfessorSang Yup Lee

-

The world’s first introduction..

□ Mathematical solution at production enterprises using Legos ○ Prof. Jang Young Jae, in charge of a supply chain management class, will give a lecture on how to manage the entire process of the production of factory goods and distribution to the consumer. The reason for using Legos in the class is to learn how to deploy and solve the actual issues of a production line of a giant factory with Legos mathematically. ○ The water purification filter production line of Woongjin Chemical Co. was renewed using a mathematical method developed by Prof. Jang to solve a problem related to production planning. ○ Woongjin Chemical faced a problem with its goods inventory, which had accumulated due to order cancellations. They made production decisions based on a mathematical system called ‘mixed integer programming’, which can determine the production volume and its type. ○ The establishment of the system using mathematics shortened the production planning time from half a day to only a few minutes and reduced the inventory by 24.5% and the production time by 23.3%. ○ This utilization of moving Lego factory ??models in industrial engineering education is the world's first case, and the experience of fabricating factory models with Legos will help students to learn how to solve the on-site mathematical problems of actual industrial factories. ○ Related Press Release: Dong-A Ilbo, Dong Science (Sep. 6, 2013) - http://news.donga.com/3/all/20130905/57492322/1

- DepartmentDepartment of Industrial & System Eng.

- ProfessorYoung Jae Jang

-

Industry-university cooperat..

□ To solve complicated logistic problems using mathematical techniques ○ Prof. Young Jae JANG from Department of Industrial and Systems Engineering at KAIST developed a system that can receive clothes in a store within two hours after a customer places an order using the mathematical theory of set cover. ○ Kolon Sports Co. demanded that customers should be allowed to receive the clothes within two hours after visiting the store. Thus, Prof. Jang‘s leading research team took advantage of the set cover theory and made it possible to ship the goods within two hours at 220 branch stores across the country. His 'Big Data Logistic System' enabled verification of the availability of goods in other stores in less than two hours and operated with the inventory management system at stores in the best place depending on the order. ○ Related Press Release: Dong-A Ilbo, Dong Science (May 9, 2014)

- DepartmentDepartment of Industrial & System Eng.

- ProfessorYoung Jae Jang

-

Introduction of the exemplary ..

□ Prof. Young Jae JANG from the Department of Industrial and Systems Engineering, KAIST contributed to improve the manufacturing system of Woongjin Chemical Co. through industry-university cooperation. ○ Woongjin Chemical Co. experienced an increase in its production of 61% due to product diversification to expand the variety of its products and capture a greater market share. However, the stock volume also increased due to customer order cancellations, increasing the inventory at the same time. ○ Mathematical techniques to solve business problems - To solve the pending problems faced by Woongjin Chemical Co. with analytic data and mathematical algorithms - To reduce Woongjin Chemical Company’s inventory by utilizing optimization techniques ○ Related Press Release: EDAILY News (July 04, 2013)

- DepartmentDepartment of Industrial & System Eng.

- ProfessorYoung Jae Jang

-

Philanthropy Design

● Philanthropy Design for charity and donation purposes through design Professor Sangmin Bae in the Industrial Design Department established the ID+IM Laboratory at KAIST and has been donating the profits of this lab earned from the designs of innovative products to unprivileged children. - The lab has developed new products and creates a profit, which is then distributed by World Vision, a Christian humanitarian organization, since 2006. - Unlike other charitable products, the Nanum project was designed to change purchasing itself as a donation, allowing customers to fulfill their convenience, innovation, and donation concurrently via Nanum products. - CrossCube, a foldable MP3 player, LovePot, a natural humidifier, and D'lghht , lightning, have been released and have won four renowned design awards (IF, IDEA, Good Design, and Red Dot) - Earnings of $1,583,310.05 from 2006, all of it used for needy children as a scholarship - Professor Sangmin Bae won the 2012 National Sharing Grand Award as a designer who creates designs that are not simply beautiful but contain exceptional functionalities and embody the meaning of sharing as well. Other than the Nanum Project, which supports needy persons domestically, he also visited Kenya four times to contribute and improve the quality of life of the Masai tribe with the 'Seed Project', involving the development of a purifier, solar-powered lighting, a traditional housing designs and other benefits.

- DepartmentDepartment of Industrial Design

- ProfessorSangmin, Bae

-

TransWall

Professor Woohun Lee’s Design Media Lab suggested the TransWall concept, which can turn a mundane glass wall into a richer interpersonal communication medium. In order to implement this idea, they created a see-through display wall touchable on both sides and added more interaction possibilities, such as the capabilities to display audio and provide vibrotactile feedback. As a result, people can collaborate via a shared see-through display and communicate with one another by talking to or even touching one another through the wall. While using the TransWall, users stand face to face. This formation is quite distinct from general interactive tabletops or shared wall displays for collocated collaboration. The TransWall is touch-sensitive on both sides so that two users can touch the same spot at the same time without any physical interference. When this happens, the TransWall provides users with specific visual, acoustic, and vibrotactile feedback such that users feel as though they are touching one another. The project was featured on Discovery Channel’s Daily Planet and on Channel 5’s The Gadget Show in 2014, and the TransWall technology has been transferred to i-KAIST Inc. (32 million KRW) and to SEMS Games Co., Ltd. (44 million KRW).

- DepartmentDepartment of Industrial Design

- ProfessorWoohun Lee

-

Internet of things and system ..

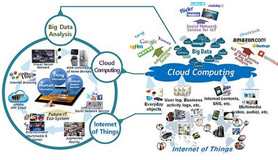

The term Internet of Things was introduced in 1999 by Kevin Ashton at the Auto-ID Labs, MIT, which is the primary research partner of GS1. GS1 is a global organization which provides various types of codes, such as bar codes, RFID codes, and QR codes for item identification, as well as a standardizing system infrastructure for global businesses and applications. Among the seven Auto-ID Labs (MIT, Cambridge, ETH Zurich, Keio, Fudan, Adelaide, and KAIST) around the world, the Auto-ID Lab at KAIST has been in the IoT field since 2002, with RFID and wireless sensor network technology. Moreover, starting in 2005, we started to develop various IoT technologies that are specialized to the GS1 standard. We are currently working on the following projects; Oliot (a GS1-based IoT infrastructure platform), SNAIL (a 6LoWPAN-based IoT connectivity platform), SeaHaven (a visual sensor network cloud platform), IoT-App Ecosystem (an ecosystem for mobile versatile applications), and GPGPU HPC Cloud (cloud computing for HPC with GPGPU). [Research Results] The IoT is the vision that aims to give everyday objects virtual personalities. The rationale behind this is to instill in objects global identification, computation and communication capabilities. That is, our everyday things become intelligent and are able to provide us with any information pertaining to the objects themselves. As a result, vast opportunities to create an entirely new dimension of services appear. In this regard, we developed the following five technologies to realize the IoT vision. (1) SNAIL: We enabled communication among things over the Internet to achieve the 6LoWPAN IoT network. SNAIL (sensor network for an All-IP world) is a solution for IoT networks in the form of a tiny IPv6-based sensor networking platform, including the complete architecture of a lightweight TCP/IP stack supporting IPv6 adaptation, ad-hoc routing, header compression, and bootstrapping as well as the four important technologies of mobility, web enablement, time synchronization, and security. (2) Oliot: The goal of Oliot is to become an IoT infrastructure platform based on international standards by extending the code system of GS1 and its standard architecture to support various IoT connectivity requirements and protocols, such as bar codes, RFID, ZigBee, and 6LoWPAN. Oliot also aims at the complete implementation of the GS1/EPCglobal standard. (3) IoT-App Ecosystem: The IoT-App Ecosystem is a new ecosystem for mobile software which enables easier interactions between mobile applications and various smart things. This is currently being implemented for Android and supports the current Android development environment. (4) SeaHaven: SeaHaven is a portable and secure multi-tenant visual sensor network cloud platform which includes a visual sensor node operating system, a visual sensor streaming service, a visual big data processing service, and user applications. The major goal of this project is to make the machine understand the context of the scene by leveraging visual sensors from around the world which are far beyond the human visual system. (5) GPGPU HPC Cloud: This project is about cloud computing for HPC with a general-purpose graphical processing unit (GPGPU). Using GPGPU on the cloud will reduce the cost and power requirements as compared to using only CPUs. We implemented the platform with OpenStack, KVM, and the API forwarding technique. [Excellency and Expected effects] (1) SNAIL: We made an effort to support secure, dynamic, global, and easy access to everyday objects using IPv6 addresses. Our IoT platform SNAIL is evaluated as a promising IoT platform. Moreover, a new version, SNAIL 2.0, will come out soon. (2) Oliot: All of the source code was opened to public and is designated to be utilized on various projects, such as the EU IoT6 Smart Building Project, the KAIST Dr. M Project, the c-ITRC Food Safety System, the Stanford Civil Engineering Project, the Korea University Hospital Project, and on Smart Consumer Electronics. A roadmap and the vision of the Oliot project are described on oliot.org. (3) IoT-App Ecosystem: With this work, mobile application developers can more easily implement applications which interact with pervasive smart things. This will also help developers publish their business logic for their customers. (4) SeaHaven: To make a machine understand the context of an event is quite a challenging task. A variety of sensors in a sparse distribution will be the most helpful key to resolving this issue. SeaHaven provides a universal interface for sensors to cover a variety of sensor devices with heterogeneity along with a highly scalable type of service architecture which allows easy scaling of the system over the cloud infrastructure. (5) GPGPU HPC Cloud: To use GPGPU on the cloud, previous approaches only support one-to-one mapping a virtual machine and a GPGPU. With the API forwarding technique and a GPGPU with the Kepler architecture, our platform supports the scalable use of GPUs. Moreover, with efficient GPU resource scheduling algorithms, our platform can maximize resource utilization metrics while providing SLA for HPC users.

- DepartmentSchool of Computing

- ProfessorDae Young Kim

-

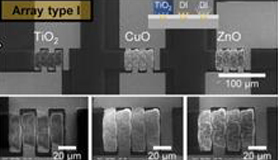

One-dimensional (1D) nanomaterials, including nanowires, nanotubes (NTs), and nanorods, have drawn a considerable amount of attention over the past decade. In particular, chemically synthesized nanowires have shown great promise for many applications due to advantages such as their high crystallinity, versatile chemical compositions, smaller dimensions, and fewer surface defects. Numerous nanowire-based devices have been reported in the literature, such as field effect transistors, memristors, field emission devices, solar cells, secondary batteries, mechanical energy harvesters, chemical sensors, photonic sensors, and biosensors. However, the controlled assembly and integration of synthesized nanowires onto the device electrodes remain as major challenges with regard to their practical and reliable applications. In this work, we developed a FEF synthesis method for the localized synthesis and integration of 1D nanomaterials. This method is based on a localized liquid-phase reaction directed by device electrodes and thus enables the selective synthesis and direct integration of nanomaterials onto microelectronic devices. A device fabricated by the FEF synthesis method exhibited excellent UV and gas sensing performance as well as outstanding physical robustness to mechanical loading conditions. This method would be very useful for the low-cost, eco-friendly, and efficient fabrication of nanostructure-integrated microelectronic devices due to its low-power, non-harsh, and simple setup as well as its excellent reliability.

- DepartmentDepartment of Mechanical Engineering

- ProfessorInkyu Park

-

Recently, gas sensors using 1D (one-dimensional) nanomaterials of metal oxides such as nanowires, nanorods and nanotubes have been actively developed because they provide a high surface-to-volume ratio, high sensitivity and a fast response speed to analyte molecules. In order to realize highly integrated sensors with 1D nanomaterials, these devices must be assembled and integrated on functional electronic chips in a controlled manner. Accordingly, various integration methods have been developed, such as dielectrophoresis, optical trapping, atomic force microscope, microfluidic flow and contact printing for the precise alignment and assembly of 1D nanomaterials. Although these methods can assemble nanomaterials on the electrodes, they have certain drawbacks with regard to the economic, high-throughput manufacturing of sensor devices. In this work, we developed a facile top-down/bottom-up hybrid nanofabrication method for the controlled synthesis of a heterogeneous nanomaterial array. The method is based on a localized, parallel liquid-phase reaction using the localized Joule heating of microheaters and a laminar flow of multiple precursor solutions with minimal interdiffusion within the microfluidic platform. This method can provide not only accurate control of the synthesis locations but also the selection of synthesized nanomaterials. With this technology, heterogeneous nanomaterials can be integrated in a microscale region without complicated alignment procedures, which is expected to be very useful for ultra-compact, low-power mobile sensors. The gas sensors fabricated by this approach exhibited good gas sensing performances for sub-ppm NO2 and gas detection in the range of tens of ppm CO, proving a strong potential towards a multiplexed gas sensing platform. Furthermore, this approach is expected to be very useful for the fabrication of numerous functional nanodevices that require a highly integrated array of heterogeneous nanomaterials, such as chemical sensors, bio sensors, field emission devices and photodetectors.

- DepartmentDepartment of Mechanical Engineering

- ProfessorInkyu Park

-

Development of an integrated ..

1. Purpose of research From the 18th century to the present, most energy requirements depended on fossil fuels and their derivatives, such as coal, natural gas, gasoline and diesel. Fossil fuels contribute to global industrialization; however, increasing fossil fuel usage contributes to several critical issues, such as global warming and environmental pollution. On account of these problem, finding a new eco-friendly, efficient and sustainable energy source is a highly significant issue for the planet. There are many groups who conduct research to find a future energy source to address this issue. Numerous candidates have been developed by scientists and researchers who study renewable energy. However, one of the most attractive energy sources is hydrogen through fuel cell system. 2. Contents of research The processing of diesel fuel for the stable operation of SOFCs was investigated. Diesel reforming is associated with several problems, including light hydrocarbon deposition, diesel delivery, the poisoning of sulfur and aromatics, and the removal of sulfur compounds and light hydrocarbons. To resolve these issues with diesel fuel processing, the diesel processor should consist of an ATR, a desulfurization process, and post-reforming reactors. ATR produces H2 and CO-rich syngas as well as sulfur compounds and light hydrocarbons in diesel ATR reformate during the desulfurization and post-reforming reaction processes. 3. Conclusion A self-sustaining 1kWe-class integrated diesel fuel processor is developed, and preliminary tests are conducted to select the reaction temperature for desulfurization and post-reforming. For effective temperature control of each reactor, the post-reforming reactor is located between the ATR reactor and the desulfurizer. The self-sustaining integrated diesel fuel processing system runs continuously for 800 hours at a gas output of 1kWe. The reforming efficiency is approximately 60%, and significant degradation of the integrated reactor does not occur. The desulfurizer and post-reforming reactor remove sulfur compounds entirely as well as residual light hydrocarbons in the diesel ATR reformate. Therefore, a self-sustaining 1kWe-class integrated diesel fuel processor is developed with Saudi-Aramco and is shown to be capable of long-term operating performance.

- DepartmentDepartment of Mechanical Engineering

- ProfessorJoongmyeon Bae

-

Optimization of an intermediat..

1. Purpose and necessity of research ?Lowering the temperature of SOFC, to make it have an low operating cost and technological advantage. ?The main goals of this research are developing reformer for low-intermediate temperautre operating SOFC and optimization of system through computational analysis. 2. Scope and contents of research ?Optimize manufactureing technology of SOFC through research in the field of ceramic manufacuting, electrode material development, stack operation and computational simulation. ?Developing catalyst reformer, method of reforming and independent reformer to optimaze fuel supplying system to SOFC. ?Optimize operating condition in reformer and SOFC total system through computational analysis about heat and fluid flow. ?Joint research with KEPCO to make SOFC stack and system, developing cathode material and reforming catalyst with Hanchang corporation and making heat exchanger for SOFC and designing system with SPEC corporation. 3. Results ?The maximum power density of 0.6 W/cm2 at 700oC was achieved by optimization of intermediate-temperature SOFC system and development of new cathode material with high catalytic activity. Cathode material of perovskite structures with Lanthanide series were also synthesized. ?To develop SOFC core technology, densification of electrolyte layer and oxidation-resistant high conductivity interconnect were studied, and a SOFC single cell stack and reforming system were developed for system control. ?Development of reforming reactor system and optimization, minimization of catalyst degradation and long-term operation, high activity structured catalyst with small size were studied. ?By CFD analysis, 3D heat and flow characteristics in SOFC single cells and reforming reactors in non-steady state conditions were studied. ?A new computational analysis method was developed, and an optimized operation strategy was suggested through optimized system design and control, such as optimal arragement of BOP, etc. Also, thermal management in a stack, fuel reformer, and heat exchanger was studied. Fig 1. Development of intermediate-temperature SOFC

- DepartmentMechanical Engineering

- ProfessorJoongmyeon Bae