Kaist

Korean

People News

-

Washing and Enrichment of Micro-Particles Encapsul..

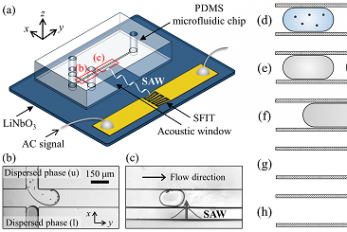

Researchers developed microfluidic technology for the washing and enrichment of in-droplet micro-particles. They presented the technology using a microfluidic chip based on surface acoustic wave (SAW)-driven acoustic radiation force (ARF). The team demonstrated the first instance of acoustic in-droplet micro-particle washing with a particle recovery rate of approximately 90 percent. They further extended the applicability of the proposed method to in-droplet particle enrichment with the unprecedented abilities to increase the in-droplet particle quantity and exchange the droplet dispersed phase. This proposed method enabled on-chip, label-free, continuous, and selective in-droplet micro-particle manipulation. The team demonstrated the first instance of in-droplet micro-particle washing between two types of alternating droplets in a simple microchannel, proving that the method can increase the particle quantity, which has not been achieved by previously reported methods. The study aimed to develop an in-droplet micro-particle washing and enrichment method based on SAW-driven ARF. When a droplet containing particles is exposed to an acoustic field, both the droplet and suspended particles experience ARF arising from inhomogeneous wave scattering at the liquid-liquid and liquid-solid interfaces. Unlike previous in-droplet particle manipulation methods, this method allows simultaneous and precise control over the droplets and suspended particles. Moreover, the proposed acoustic method does not require labelled particles, such as magnetic particles, and employs a simple microchannel geometry. Microfluidic sample washing has emerged as an alternative to centrifugation because the limitations of centrifugation-based washing methods can be addressed using continuous washing processes. It also has considerable potential and importance in a variety of applications such as single-cell/particle assays, high-throughput screening of rare samples, and cell culture medium exchange. Compared to continuous flow-based microfluidic methods, droplet-based microfluidic sample washing has been rarely explored due to technological difficulties. On-chip, in-droplet sample washing requires sample transfer across the droplet interface composed of two immiscible fluids. This process involves simultaneous and precise control over the encapsulated sample and droplet interface during the medium exchange of the in-droplet sample. Sample encapsulation within individual microscale droplets offers isolated microenvironments for the samples. Experimental uncertainties due to cross-contamination and Taylor dispersion between multiple reagents can be reduced in droplet-based microfluidics. This is the first research achievement made by the Acousto-Microfluidics Research Center for Next-Generation Healthcare, the cross-generation collaborative lab KAIST opened in May. This novel approach pairs senior and junior faculty members for sustaining the research legacy even after the senior researcher retires. The research center, which paired Chair Professor Hyung Jin Sung and Professors Hyoungsoo Kim and Yeunwoo Cho, made a breakthrough in microfluidics along with PhD candidate Jinsoo Park. The study was featured as the cover of Lab on a Chip published by Royal Society of Chemistry. Jinsoo Park, first author of the study, believes this technology will may serve as an in-droplet sample preparation platform with in-line integration of other droplet microfluidic components. Chair Professor Sung said, “The proposed acoustic method will offer new perspectives on sample washing and enrichment by performing the operation in microscale droplets.” Figure 1. (a) A microfluidic device for in-droplet micro-particle washing and enrichment; (b) alternatingly produced droplets of two kinds at a double T-junction; (c) a droplet and encapsulated micro-particles exposed to surface acoustic wave-driven acoustic radiation force; (d-h) sequential processes of in-droplet micro-particle washing and enrichment operation.

-

Flexible Piezoelectric Acoustic Sensors for Speake..

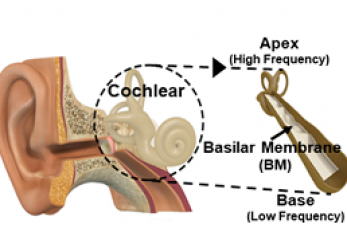

A KAIST research team led by Professor Keon Jae Lee from the Department of Material Science and Engineering has developed a machine learning-based acoustic sensor for speaker recognition. Acoustic sensors were spotlighted as one of the most intuitive bilateral communication devices between humans and machines. However, conventional acoustic sensors use a condenser-type device for measuring capacitance between two conducting layers, resulting in low sensitivity, short recognition distance, and low speaker recognition rates. The team fabricated a flexible piezoelectric membrane by mimicking the basilar membrane in the human cochlear. Resonant frequencies vibrate corresponding regions of the trapezoidal piezoelectric membrane, which converts voice to electrical signal with a highly sensitive self-powered acoustic sensor. This multi-channel piezoelectric acoustic sensor exhibits sensitivity more than two times higher and allows for more abundant voice information compared to conventional acoustic sensors, which can detect minute sounds from farther distances. In addition, the acoustic sensor can achieve a 97.5% speaker recognition rate using a machine learning algorithm, reducing by 75% error rate than the reference microphone. AI speaker recognition is the next big thing for future individual customized services. However, conventional technology attempts to improve recognition rates by using software upgrades, resulting in limited speaker recognition rates. The team enhanced the speaker recognition system by replacing the existing hardware with an innovative flexible piezoelectric acoustic sensor. Further software improvement of the piezoelectric acoustic sensor will significantly increase the speaker and voice recognition rate in diverse environments. Professor Lee said, “Highly sensitive self-powered acoustic sensors for speaker recognition can be used for personalized voice services such as smart home appliances, AI secretaries, always-on IoT, biometric authentication, and FinTech.” These research “Basilar Membrane-Inspired Self-Powered Acoustic Sensor” and “Machine Learning-based Acoustic Sensor for Speaker Recognition” were published in the September 2018 issue of Nano Energy. Firgure 1: A flexible piezoelectric acoustic sensor mimicking the human cochlear. Figure 2: Speaker recognition with a machine learning algorithm.

-

Engineered E. coli Using Formic Acid and CO2 As a ..

(Figure: Formic acid and CO2 assimilation pathways consisting of the reconstructed THF cycle and reverse glycine cleavage reaction. This schematic diagram shows the formic acid and CO2 assimilation procedure through the pathway. Plasmids used in this study and the genetic engineering performed in this study are illustrated.) A research group at KAIST has developed an engineered E. coli strain that converts formic acid and CO2 to pyruvate and produces cellular energy from formic acid through reconstructed one-carbon pathways. The strategy described in this study provides a new platform for producing value-added chemicals from one-carbon sources. Formic acid is a carboxylic acid composed of one carbon. Formic acid was produced from CO2 by the chemical method. Recently, the C1 Gas Refinery R&D Center has successfully developed a biological process that produces formic acid from carbon monoxide for the first time. Formic acid is in a liquid state when at room temperature and atmospheric pressure. In addition, it is chemically stable and less toxic, thus, easy to store and transport. Therefore, it can be used as an alternative carbon source in the microbial fermentation process. In order to produce value-added chemicals using formic acid, a metabolic pathway that converts formic acid into cellular molecules composed of multiple carbons is required. However, a metabolic pathway that can efficiently convert formic acid into cellular molecules has not been developed. This acted as an obstacle for the production of value-added chemicals using formic acid A research group of Ph.D. student Junho Bang and Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering addressed this issue. This study, entitled “Assimilation of Formic Acid and CO2 by Engineered Escherichia coli Equipped with Reconstructed One-Carbon Assimilation Pathways”, has been published online in the Proceedings of the National Academy of Sciences of the United States of America (PNAS) on September 18. There has been increasing interest in utilizing formic acid as an alternative carbon source for the production of value-added chemicals. This research reports the development of an engineered E. coli strain that can convert formic acid and CO2 to pyruvate and produce cellular energy from formic acid through the reconstructed one-carbon pathways. The metabolic pathway that efficiently converts formic acid and CO2 into pyruvate was constructed by the combined use of the tetrahydrofolate cycle and reverse glycine cleavage reaction. The tetrahydrofolate cycle was reconstructed by utilizing Methylobacterium extorquens formate-THF ligase, methenyl-THF cyclohydrolase, and methylene-THF dehydrogenase. The glycine cleavage reaction was reversed by knocking out the repressor gene (gcvR) and overexpressing the gcvTHP genes that encode enzymes related with the glycine cleavage reaction. Formic acid and CO2 conversion to pyruvate was increased via metabolic engineering of the E. coli strain equipped with the one-carbon assimilation pathway. In addition, in order to reduce glucose consumption and increase formic acid consumption, Candida boidnii formate dehydrogenase was additionally introduced to construct a cellular energy producing pathway from formic acid. This reduces glucose consumption and increases formic acid consumption. The reconstructed one-carbon pathways can supply cellular molecules and cellular energies from the formic acid and CO2. Thus, the engineered E. coli strain equipped with the formic acid and CO2 assimilation pathway and cellular energy producing pathway from formic acid showed cell growth from formic acid and CO2 without glucose. Cell growth was monitored and 13C isotope analysis was performed to confirm E. coli growth from the formic acid and CO2. It was found that the engineered E. coli strain sustained cell growth from the formic acid and CO2 without glucose. Professor Lee said, “To construct the C1-refinery system, a platform strain that can convert one-carbon materials to higher carbon materials needs to be developed. In this report, a one-carbon pathway that can efficiently convert formic acid and CO2 to pyruvate was developed and a cellular energy producing pathway from formic acid was introduced. This resulted in an engineered E. coli strain that can efficiently utilize formic acid as a carbon source while glucose consumption was reduced. The reconstructed one-carbon pathways in this research will be useful for the construction of the C1-refinery system.” This work was supported by the C1 Gas Refinery Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (NRF-2016M3D3A1A01913250). For further information: Sang Yup Lee, Distinguished Professor of Chemical and Biomolecular Engineering, KAIST (leesy@kaist.ac.kr, Tel: +82-42-350-3930)

-

KAIST Perfectly Transfers Nanowires onto a Flexibl..

(from left: PhD Min-Ho Seo and Professor Jun-Bo Yoon) Boasting excellent physical and chemical properties, nanowires (NWs) are suitable for fabricating flexible electronics; therefore, technology to transfer well-aligned wires plays a crucial role in enhancing performance of the devices. A KAIST research team succeeded in developing NW-transfer technology that is expected to enhance the existing chemical reaction-based NW fabrication technology that has this far showed low performance in applicability and productivity. NWs, one of the most well-known nanomaterials, have the structural advantage of being small and lightweight. Hence, NW-transfer technology has drawn attention because it can fabricate high-performance, flexible nanodevices with high simplicity and throughput. A conventional nanowire-fabrication method generally has an irregularity issue since it mixes chemically synthesized nanowires in a solution and randomly distributes the NWs onto flexible substrates. Hence, numerous nanofabrication processes have emerged, and one of them is master-mold-based, which enables the fabrication of highly ordered NW arrays embedded onto substrates in a simple and cost-effective manner, but its employment is limited to only some materials because of its chemistry-based NW-transfer mechanism, which is complex and time consuming. For the successful transfer, it requires that adequate chemicals controlling the chemical interfacial adhesion between the master mold, NWs, and flexible substrate be present. Here, Professor Jun-Bo Yoon and his team from the School of Electrical Engineering introduced a material-independent mechanical-interlocking-based nanowire-transfer (MINT) method to fabricate ultralong and fully aligned NWs on a large flexible substrate in a highly robust manner. This method involves sequentially forming a nanosacrificial layer and NWs on a nanograting substrate that becomes the master mold for the transfer, then weakening the structure of the nanosacrificial layer through a dry etching process. The nanosacrificial layer very weakly holds the nanowires on the master mold. Therefore, when using a flexible substrate material, the nanowires are very easily transferred from the master mold to the substrate, just like a piece of tape lifting dust off a carpet. This technology uses common physical vapor deposition and does not rely on NW materials, making it easy to fabricate NWs onto the flexible substrates. Using this technology, the team was able to fabricate a variety of metal and metal-oxide NWs, including gold, platinum, and copper – all perfectly aligned on a flexible substrate. They also confirmed that it can be applied to creating stable and applicable devices in everyday life by successfully applying it to flexible heaters and gas sensors. PhD Min-Ho Seo who led this research said, “We have successfully aligned various metals and semiconductor NWs with excellent physical properties onto flexible substrates and applied them to fabricated devices. As a platform-technology, it will contribute to developing high-performing and stable electronic devices.” This research was published in ACS Nano on May 24. Figure 1. Photograph of the fabricated wafer-scale fully aligned and ultralong Au nanowire array on a flexible substrate

-

Silk Adhesive Paves the Way for Epidermal Electron..

(from left: Dr. Ji-Won Seo, Professor Hyunjoo Jenny Lee and PhD candidate, Hyojung Kim) Producing effective epidermal electronics requires a strong, biocompatible interface between a biological surface and a sensor. Here, a KAIST team employed a calcium-modified silk fibroin as a biocompatible and strong adhesive. This technology led to the development of epidermal electronics with strong adhesion for patients who need drug injections and physiological monitoring over a long time. Recently, biocompatible silk fibroins has been increasingly used for flexible substrates and water-soluble sacrificial layers because they allow structural modifications and are biodegradable. From previous studies, the team discovered the adhesive properties of silk fibroin via metal chelate bonding and the water-capturing of Ca ions. Professor Hyunjoo Jenny Lee from the School of Electrical Engineering and her team explored ways to develop reusable, water-degradable, biocompatible and conductive epidermal electronics that can be attached to the human skin for long-term use. To overcome the limitations of conventional silk fibroin, the team introduced Ca ions to modify silk fibroin into a strong and biocompatible adhesive. Calcium ions adopted in silk fibroins serve to capture water and enhance the cohesion force through metal chelation. Therefore, this endows viscoelasticity to previously a firm silk fibroin. This modified silk fibroin exhibits strong viscoelasticity and strong adhesiveness when physically attached to the human skin and various polymer substrates. Their developed silk adhesive is reusable, water-degradable, biocompatible, and conductive. To test the effectiveness, the team employed the silk adhesive to fabricate an epidermal capacitive touch sensor that can be attached to the human skin. They verified the reusability of the sensor by performing attachment and detachment tests. They also confirmed that the physical adhesion of the Ca-modified silk facilitates its reusability and possesses high peel strength. Furthermore, they tested the stretchability of the silk adhesive on bladder tissue. Although it is not an epidermal skin, bladder tissue is highly stretchable. Hence, it is a perfect target to measure the resistance-strain characteristic of the silk adhesive. When the bladder tissue was stretched, the resistive strain epidermal sensor corresponded to the tensile strain. Showing high biocompatibility, the silk adhesive is suitable for interfacing with the human skin for a long period of time. Therefore, it can also be applied to a drug delivery epidermal system as well as an electrocardiogram (ECG) epidermal sensor. Professor Lee said, “We are opening up a novel use for silk by developing reusable and biodegradable silk adhesive using biocompatible silk fibroin. This technology will contribute to the development of next-generation epidermal electronics as well as drug delivery systems. This research, led by Dr. Ji-Won Seo and a PhD candidate, Hyojung Kim, was published in Advanced Functional Materials on September 5, 2018. Figure 1. Schematic and photograph of a hydrogel patch adhered on the human skin through the silk adhesive Figure 2. Cover page of Advanced Functional Materials

-

Spray Coated Tactile Sensor on a 3-D Surface for R..

Robots will be able to conduct a wide variety of tasks as well as humans if they can be given tactile sensing capabilities. A KAIST research team has reported a stretchable pressure insensitive strain sensor by using an all solution-based process. The solution-based process is easily scalable to accommodate for large areas and can be coated as a thin-film on 3-dimensional irregularly shaped objects via spray coating. These conditions make their processing technique unique and highly suitable for robotic electronic skin or wearable electronic applications. The making of electronic skin to mimic the tactile sensing properties of human skin is an active area of research for various applications such as wearable electronics, robotics, and prosthetics. One of the major challenges in electronic skin research is differentiating various external stimuli, particularly between strain and pressure. Another issue is uniformly depositing electrical skin on 3-dimensional irregularly shaped objects. To overcome these issues, the research team led by Professor Steve Park from the Department of Materials Science and Engineering and Professor Jung Kim from the Department of Mechanical Engineering developed electronic skin that can be uniformly coated on 3-dimensional surfaces and distinguish mechanical stimuli. The new electronic skin can also distinguish mechanical stimuli analogous to human skin. The structure of the electronic skin was designed to respond differently under applied pressure and strain. Under applied strain, conducting pathways undergo significant conformational changes, considerably changing the resistance. On the other hand, under applied pressure, negligible conformational change in the conducting pathway occurs; e-skin is therefore non-responsive to pressure. The research team is currently working on strain insensitive pressure sensors to use with the developed strain sensors. The research team also spatially mapped the local strain without the use of patterned electrode arrays utilizing electrical impedance tomography (EIT). By using EIT, it is possible to minimize the number of electrodes, increase durability, and enable facile fabrication onto 3-dimensional surfaces. Professor Park said, “Our electronic skin can be mass produced at a low cost and can easily be coated onto complex 3-dimensional surfaces. It is a key technology that can bring us closer to the commercialization of electronic skin for various applications in the near future.” The result of this work entitled “Pressure Insensitive Strain Sensor with Facile Solution-based Process for Tactile Sensing Applications” was published in the August issue of ACS Nano as a cover article. (Figure: Detecting mechanical stimuli using electrical impedance tomography

-

KAIST First Reveals Principles behind Electron Hea..

(from left: Professor Wonho Choe and Research Professor Sanghoo Park) A KAIST research team successfully identified the underlying principles behind electron heating, which is one of the most important phenomena in plasmas. As the electric heating determines wide range of physical and chemical properties of plasmas, this outcome will allow relevant industries to extend and effectively customize a range of plasma characteristics for their specific needs. Plasma, frequently called the fourth state of matter, can be mostly formed by artificially energizing gases in standard temperature (25°C) and pressure (1 atm) range. Among the many types of plasma, atmospheric-pressure plasmas have been gaining a great deal of attention due to their unique features and applicability in various scientific and industrial fields. Because plasma characteristics strongly depends on gas pressure in the sub-atmospheric to atmospheric pressure range, characterizing the plasma at different pressures is a prerequisite for understanding the fundamental principles of plasmas and for their industrial applications. In that sense, information on the spatio-temporal evolution in the electron density and temperature is very important because various physical and chemical reactions within a plasma arise from electrons. Hence, electron heating has been an interesting topic in the field of plasma. Because collisions between free electrons and neutral gases are frequent under atmospheric-pressure conditions, there are physical limits to measuring the electron density and temperature in plasmas using conventional diagnostic tools, thus the principles behind free electron heating could not be experimentally revealed. Moreover, lacking information on a key parameter of electron heating and its controlling methods is troublesome and limit improving the reactivity and applicability of such plasmas. To address these issues, Professor Wonho Choe and his team from the Department of Nuclear and Quantum Engineering employed neutral bremsstrahlung-based electron diagnostics in order to accurately examine the electron density and temperature in target plasmas. In addition, a novel imaging diagnostics for two dimensional distribution of electron information was developed. Using the diagnostic technique they developed, the team measured the nanosecond-resolved electron temperature in weakly ionized collisional plasmas, and they succeeded in revealing the spatiotemporal distribution and the fundamental principle involved in the electron heating process. The team successfully revealed the fundamental principle of the electron heating process under atmospheric to sub-atmospheric pressure (0.25-1atm) conditions through conducting the experiment on the spatiotemporal evolution of electron temperature. Their findings of the underlying research data on free electrons in weakly ionized collisional plasmas will contribute to enhancing the field of plasma science and their commercial applications. Professor Choe said, “The results of this study provide a clear picture of electron heating in weakly ionized plasmas under conditions where collisions between free electrons and neutral particles are frequent. We hope this study will be informative and helpful in utilizing and commercializing atmospheric-pressure plasma sources in the near future.” Articles related to this research, led by Research Professor Sanghoo Park, were published in Scientific Reports on May 14 and July 5. Figure 1. Nanosecond-resolved visualization of the electron heating structure. Spatiotemporal evolution of 514.5-nm continuum radiation,Te, Ar I emission Figure 2. Nanosecond-resolved visualization of electron heating. Spatiotemporal evolution of neutral bremsstrahlung at 514.5 nm

-

Distinguished Professor Sang Yup Lee Announced as ..

(Distinguished Professor Sang Yup Lee) Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering will be awarded the 2018 Eni Advanced Environmental Solutions Prize in recognition of his innovations in the fields of energy and environment. The award ceremony will take place at the Quirinal Palace, the official residence of Italian President Sergio Mattarella, who will also be attending on October 22. Eni, an Italian multinational energy corporation established the Eni Award in 2008 to promote technological and research innovation of efficient and sustainable energy resources. The Advanced Environmental Solutions Prize is one of the three categories of the Eni Award. The other two categories are Energy Transition and Energy Frontiers. The Award for Advanced Environmental Solutions recognizes a researcher or group of scientists that has achieved internationally significant R&D results in the field of environmental protection and recovery. The Eni Award is referred to as the Nobel Award in the fields of energy and environment. Professor Lee, a pioneering leader in systems metabolic engineering was honored with the award for his developing engineered bacteria to produce chemical products, fuels, and non-food biomass materials sustainably and with a low environmental impact. He has leveraged the technology to develop microbial bioprocesses for the sustainable and environmentally friendly production of chemicals, fuels, and materials from non-food renewable biomass. The award committee said that they considered the following elements in assessing Professor Lee’s achievement: the scientific relevance and the research innovation level; the impact on the energy system in terms of sustainability as well as fairer and broader access to energy; and the adequacy between technological and economic aspects. Professor Lee, who already won two other distinguished prizes such as the George Washington Carver Award and the PV Danckwerts Memorial Lecture Award this year, said, “I am so glad that the international academic community as well as global industry leaders came to recognize our work that our students and research team has made for decades.” Dr. Lee’s lab has been producing a lot of chemicals in environmentally friendly ways. Among them, many were biologically produced for the first time and some of these processes have been already commercialized. “We will continue to strive for research outcomes with two objectives: First, to develop bio-based processes suitable for sustainable chemical industry. The other is to contribute to the human healthcare system through development of platform technologies integrating medicine and nutrition,” he added.

-

AI-based Digital Watermarking to Beat Fake News

(from left: PhD candidates Ji-Hyeon Kang, Seungmin Mun, Sangkeun Ji and Professor Heung-Kyu Lee) The illegal use of images has been a prevalent issue along with the rise of distributing fake news, which all create social and economic problems. Here, a KAIST team succeeded in embedding and detecting digital watermarks based on deep neural learning artificial intelligence, which adaptively responds to a variety of attack types, such as removing watermarks and hacking. Their research shows that this technology reached a level of reliability for technology commercialization. Conventional watermarking technologies show limitations in terms of practicality, technology scalability, and usefulness because they require a predetermined set of conditions, such as the attack type and intensity. They are designed and implemented in a way to satisfy specific conditions. In addition to those limitations, the technology itself is vulnerable to security issues because upgraded hacking technologies are constantly emerging, such as watermark removal, copying, and substitution. Professor Heung-Kyu Lee from the School of Computing and his team provided a web service that responds to new attacks through deep neural learning artificial intelligence. It also serves as a two-dimensional image watermarking technique based on neural networks with high security derived from the nonlinear characteristics of artificial neural networks. To protect images from varying viewpoints, the service offers a depth-image-based rendering (DIBR) three-dimensional image watermarking technique. Lastly, they provided a stereoscopic three-dimensional (S3D) image watermarking technique that minimizes visual fatigue due to the embedded watermarks. Their two-dimensional image watermarking technology is the first of its kind to be based upon artificial neural works. It acquires robustness through educating the artificial neural networking on various attack scenarios. At the same time, the team has greatly improved on existing security vulnerabilities by acquiring high security against watermark hacking through the deep structure of artificial neural networks. They have also developed a watermarking technique embedded whenever needed to provide proof during possible disagreements. Users can upload their images to the web service and insert the watermarks. When necessary, they can detect the watermarks for proof in any dispute. Moreover, this technology provides services, including simulation tools, watermark adjustment, and image quality comparisons before and after the watermark is embedded. This study maximized the usefulness of watermarking technology by facilitating additional editing and demonstrating robustness against hacking. Hence, this technology can be applied in a variety of contents for certification, authentication, distinction tracking, and copyrights. It can contribute to spurring the content industry and promoting a digital society by reducing the socio-economic losses caused by the use of various illegal image materials in the future. Professor Lee said, “Disputes related to images are now beyond the conventional realm of copyrights. Recently, their interest has rapidly expanded due to the issues of authentication, certification, integrity inspection, and distribution tracking because of the fake video problem. We will lead digital watermarking research that can overcome the technical limitations of conventional watermarking techniques.” This technology has only been conducted in labs thus far, but it is now open to the public after years of study. His team has been conducting a test run on the webpage (click).Moving forward from testing the technology under specific lab conditions, it will be applied to a real environment setting where constant changes pervade. 1. Figure. 2D image using the watermarking technique: a) original image b) watermark-embedded image c) signal from the embedded watermark Figure 2. Result of watermark detection according to the password Figure 3. Example of a center image using the DIBR 3D image watermarking technique: a) original image b) depth image c) watermark-embedded image d) signal from the embedded watermark Figure 4. Example of using the S3D image watermarking technique: a) original left image b) original right image c) watermark-embedded left image d) watermark-embedded right image e) signal from the embedded watermark (left) f) signal from the embedded watermark (right)

-

Rh Ensemble Catalyst for Effective Automobile Exha..

(from left: Professor Hyunjoo Lee and PhD candidate Hojin Jeong) A KAIST research team has developed a fully dispersed Rh ensemble catalyst (ENS) that shows better performance than commercial diesel oxidation catalyst (DOC). This newly developed ENSs could improve low-temperature automobile exhaust treatment. Precious metals have been used for various heterogeneous reactions, but it is crucial to maximize efficiency of catalysts due to their high cost. Single-atom catalysts (SACs) have received much attention because it is possible for all of the metal atoms to be used for reactions, yet they do not show catalytic activity for reactions that require ensemble sites. Meanwhile, hydrocarbons, such as propylene (C3H6) and propane (C3H8) are typical automobile exhaust gas pollutants and must be converted to carbon dioxide (CO2) and water (H2O) before they are released as exhaust. Since the hydrocarbon oxidation reaction proceeds only during carbon-carbon (C-C) or carbon-hydrogen (C-H) bond cleavage, it is essential to secure the metal ensemble site for the catalytic reaction. Therefore, precious metal catalysts with high dispersion and ensemble sites are greatly needed. To solve this issue, Professor Hyunjoo Lee from the Department of Chemical and Biomolecular Engineering and Professor Jeong Woo Han from POSTECH developed an Rh ensemble catalyst with 100% dispersion, and applied it to automobile after-treatment. Having a 100% dispersion means that every metal atom is used for the reaction since it is exposed on the surface. SACs also have 100% dispersion, but the difference is that ENSs have the unique advantage of having an ensemble site with two or more atoms. As a result of the experiment, the ENSs showed excellent catalytic performance in CO, NO, propylene, and propane oxidation at low temperatures. This complements the disadvantage of nanoparticle catalyst (NPs) that perform catalysis poorly at low temperatures due to low metal dispersion, or SACs without hydrocarbon oxidation. In particular, the ENSs have superior low-temperature activity even better than commercial DOC, hence they are expected to be applied to automobile exhaust treatment. Professor Lee said, “I believe that the ENSs have given academic contribution for proposing a new concept of metal catalysts, differentiating from conventional SACs and NPs. At the same time, they are of great value in the industry of exhaust treatment catalysts.” This research, led by PhD candidate Hojin Jeong, was published in the Journal of the American Chemical Society on July 5. Figure 1. Concept of Rh ensemble catalyst for automobile exhaust treatment Figure 2. Structure and performance comparison of single-atom catalyst and ensemble catalyst Figure 3. Energy-dispersive X-ray spectroscopy (EDS) mapping images for SAC, ENS, and NP, respectively (green, Eh; red, Ce)

-

Skin Hardness to Estimate Better Human Thermal Sta..

(Professor Young-Ho Cho and Researcher Sunghyun Yoon) Under the same temperature and humidity, human thermal status may vary due to individual body constitution and climatic environment. A KAIST research team previously developed a wearable sweat rate sensor for human thermal comfort monitoring. Furthering the development, this time they proposed skin hardness as an additional, independent physiological sign to estimate human thermal status more accurately. This novel approach can be applied to developing systems incorporating human-machine interaction, which requires accurate information about human thermal status. Professor Young-Ho Cho and his team from the Department of Bio and Brain Engineering had previously studied skin temperature and sweat rate to determine human thermal comfort, and developed a watch-type sweat rate sensor that accurately and steadily detects thermal comfort last February (title: Wearable Sweat Rate Sensors for Human Thermal Comfort Monitoring ). However, skin temperature and sweat rate are still not enough to estimate exact human thermal comfort. Hence, an additional indicator is required for enhancing the accuracy and reliability of the estimation and the team selected skin hardness. When people feel hot or cold, arrector pili muscles connected to hair follicles contract and expand, and skin hardness comes from this contraction and relaxation of the muscles. Based on the phenomenon of changing skin hardness, the team proposed skin hardness as a new indicator for measuring human thermal sensation. With this new estimation model using three physiological signs for estimating human thermal status, the team conducted human experiments and verified that skin hardness is effective and independent from the two conventional physiological signs. Adding skin hardness to the conventional model can reduce errors by 23.5%, which makes its estimation more reliable. The team will develop a sensor that detects skin hardness and applies it to cognitive air-conditioning and heating systems that better interact with humans than existing systems. Professor Cho said, “Introducing this new indicator, skin hardness, elevates the reliability of measuring human thermal comfort regardless of individual body constitution and climatic environment. Based on this method, we can develop a personalized air conditioning and heating system that will allow affective interaction between humans and machines by sharing both physical and mental health conditions and emotions.” This research, led by researchers Sunghyun Yoon and Jai Kyoung Sim, was published in Scientific Reports, Vol.8, Article No.12027 on August 13, 2018. (pp.1-6) Figure 1. Measuring human thermal status through skin hardness Figure 2. The instrument used for measuring human thermal status through skin hardness

-

KAIST Introduces Faster and More Powerful Aqueous ..

(Professor Jeung Ku Kang from the Graduate School of EEWS) A KAIST research team made it one step closer to realizing safe energy storage with high energy density, high power density, and a longer cycle life. This hybrid storage alternative shows power density 100 times faster than conventional batteries, allowing it to be charged within a few seconds. Hence, it is suitable for small portable electronic devices. Conventional electrochemical energy storage systems, including lithium-ion batteries (LIBs), have a high voltage range and energy density, but are subject to safety issues raised by flammable organic electrolytes, which are used to ensure the beneficial properties. Additionally, they suffer from slow electrochemical reaction rates, which lead to a poor charging rate and low power density with a capacity that fades quickly, resulting in a short cycle life. On the other hand, capacitors based on aqueous electrolytes are receiving a great deal of attention because they are considered to be safe and environmentally friendly alternatives. However, aqueous electrolytes lag behind energy storage systems based on organic electrolytes in terms of energy density due to their limited voltage range and low capacitance. Hence, developing aqueous energy storage with high energy density and a long cycle life in addition to the high power density that enables fast charging is the most challenging task for advancing next-generation electrochemical energy storage devices. Here, Professor Jeung Ku Kang from the Graduate School of Energy, Environment, Water and Sustainability and his team developed an aqueous hybrid capacitor (AHC) that boasts high energy density, high power, and excellent cycle stability by synthesizing two types of porous metal oxide nanoclusters on graphene to create positive and negative electrodes for AHCs. The porous metal oxide nanoparticles are composed of nanoclusters as small as two to three nanometers and have mesopores that are smaller than five nanometers. In these porous structures, ions can be rapidly transferred to the material surfaces and a large number of ions can be stored inside the metal oxide particles very quickly due to their small particle size and large surface area. The team applied porous manganese oxide on graphene for positive electrodes and porous iron oxide on graphene for negative electrodes to design an aqueous hybrid capacitor that can operate at an extended voltage range of 2V. Professor Kang said, “This newly developed AHC with high capacity and power density driven from porous metal oxide electrodes will contribute to commercializing a new type of energy storage system. This technology allows ultra-fast charging within several seconds, making it suitable as a power source for mobile devices or electric vehicles where solar energy is directly stored as electricity.” This research, co-led by Professor Hyung Mo Jeong from Kangwon National University, was published in Advanced Functional Materials on August 15, 2018. Figure 1. Image that shows properties of porous metal oxide nanoparticles formed on graphene in the aqueous hybrid capacitor